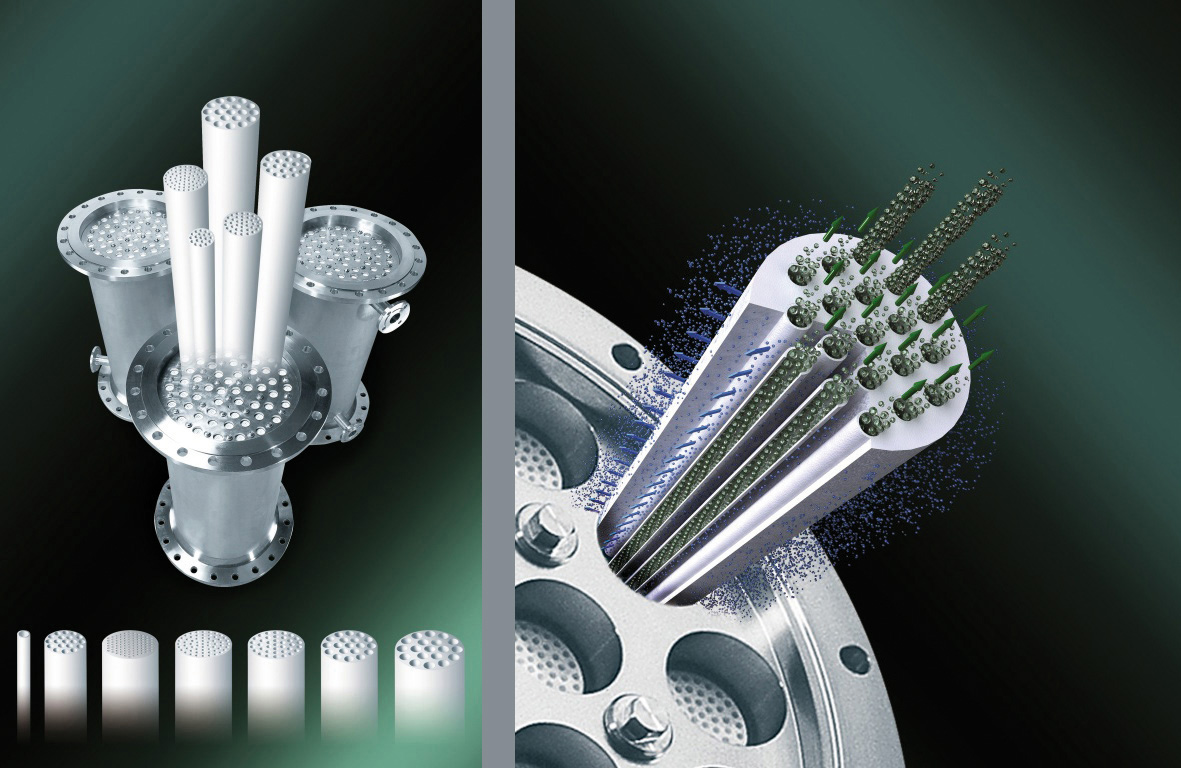

At Intervitis Interfructa 2013, GEA Westfalia Separator Group presented its extended range of ceramic membranes. These allow an increased concentration of solids in cross-flow filtration, requiring no further treatment. This gives rise to highly efficient filtration processes for beverage and dairy technology. Under the brand of established membrane producer Membraflow, GEA Westfalia Separator Group offers different membrane types depending on the application. Here, the ceramic filter elements, modules and accessories are configured individually for the respective purpose.

Concentration tasks such as beer recovery from surplus yeast use ceramic membrane elements virtually exclusively. With ceramic membranes, high solid dry substances with constantly high filtrate flux rates can be achieved over the entire life cycle. Ceramic membranes have a durability of over ten years, therefore representing a longer term solution and allowing free choice of the most advantageous pore size for an optimum result. Overall, ceramic membranes therefore work with a lower total cost of ownership than polymer membranes for example.

Broad spectrum for high flexibility

The ceramic membrane elements with different structures form the centrepiece of a membrane filtration system. Several such elements are installed in one module. Membraflow offers a broad spectrum of membrane elements, allowing optimal configuration depending on application and product. The channel diameter can vary from a unique 1.3 mm to 8 mm and the pore size from 5 nm (0.005 µm) to 1.4 µm. The number of channels here ranges from one to over 277. The length of the membrane elements can also be produced flexibly. Moreover, GEA Westfalia Separator Group also supplies module housings, backwashing units and sealing accessories.

The users of Membraflow ceramic membrane filter elements benefit from the full support of over 50 sales and service companies as well as 20 GEA Westfalia Separator Group authorized workshops all over the world. |