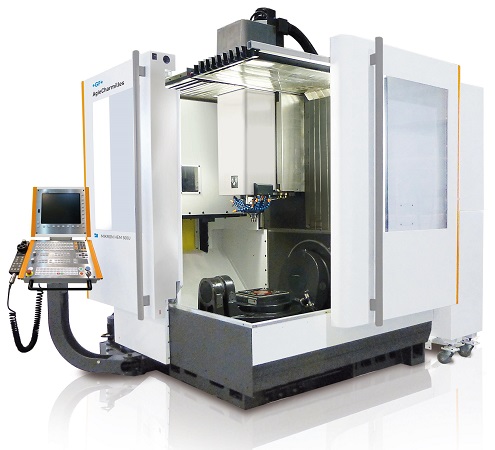

HEM 500U: flexible, affordable, functional Milling solution

Flexibility, a compact and simple design, and ease of use are the hallmarks of the new five-axis Milling machine from GF AgieCharmilles. The universal HEM 500U is especially suitable for parts production in fields like aerospace and aeronautics and general machinery.

The HEM 500U underscores GF AgieCharmilles’ commitment to meeting customers’ needs for flexible, competitively priced and easy-to-use standard five-axis Milling solutions.

The HEM 500U with its new developed rotary tilting table persuades with competitive performance in terms of stiffness and versatility in its class. It is the ergonomic answer for the standard production of precision parts in prototyping up to series from five workpieces with wide-opening doors. The HEM 500U offers a good view of the machining process and easy loading and access to the work piece.

This functional and easy to use Milling solution comes with Heidenhain’s iTNC 530 control enabling production of highly accurate work piece contours while machining at high velocity.

It matches perfectly with the machine, a reliable and sturdy five-axis Milling centre for all kinds of “3+2” Milling jobs. The control’s uniformly digital design ensures high accuracy and surface quality, as well as high traverse speeds.

Compact and stiff design and easy Automation accessibility

The machine is designed as a robust C-Frame structure supporting a cross-sledge for the transversal X- and Y- movements. All three linear axes are located on a sturdy block that houses the B-axis. The vertical Z-movement, housing an inline spindle, is mounted to the rigid Y-axis column.

The compact combination of spindle slides/machine columns absorbs the forces resulting from the machining process. The structure stiffness allows both rapid and precise displacement of the moving element. All the structural components are manufactured in cast iron. This material possesses very good vibration dampening characteristics. Set up of the machine takes place on the leveling elements also supplied. No special foundation is necessary. Customers considering future pallet Automation can choose a “preparation for Automation” option at order placement, and then later add the Automation system which is qualified for their needs.

Whether the customer is machining aluminium or steel, the HEM 500U represents accuracy, flexibility, affordability and ease of use across a wide range of applications. From machining structural parts for aircraft to components for electronics boxes, the HEM 500U is this standard machining solution of choice from GF AgieCharmilles.

Customer Services

Like all GF AgieCharmilles products, the HEM 500U is supported by a continuum of Customer Services customizable to your particular needs. GF AgieCharmilles’ Customer Services offers the industry’s most comprehensive service package: preventive services, training, a dedicated Helpline, original wear parts and certified consumables, and a Privilege Club with special advantages available only to GF AgieCharmilles customers. |

| Acerca de esta empresa: |

| GF AgieCharmilles is the world’s leading provider of machines, Automation solutions and services to the tool and mold making industry and to manufacturers of precision components. Products range from electric discharge machines and high-speed and high-performance Milling machines - including clamping and palletization systems - to 3D Laser surface texturing machines, services, spare and expendable parts, consumables, and Automation solutions. |

| Empresa: |

| Nombre de la empresa: |

Agie Charmilles Management SA |

| dirección: |

Rue du Pré-de-la-Fontaine 8, 1217 Meyrin 1 |

| ciudad: |

Geneva |

| provincia: |

|

| ZIP: |

6616 |

| país: |

Switzerland |

| número de teléfono: |

+41-22-783 31 11 |

| FAX: |

+41-22-783 06 12 |

|

|

|