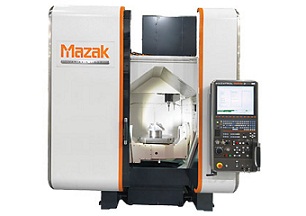

The Mazak VARIAXIS i-600 Multi-Tasking Vertical Machining Center debuted at T3 – Tomorrow's Technology Today, a 2011 Discover Mazak event. The full simultaneous 5-axis high-speed machine showed its exceptional capability for handling workpieces up to 27.56" (700 mm) in diameter and 17.72" (450 mm) high and for those complex components, such as impellers, requiring ample Y-axis and Z-axis machine strokes.

Mazak designed the VARIAXIS i-600 with an extended Y-axis stroke of 35.83" (910 mm) and X- and Z-axis strokes of 20.08" (510 mm), which together expand the machine's working envelope capacity. Rapid feedrates of 2,362 ipm (60 m/min) in X- and Y-axes, as well as a 2,205 ipm (56 m/min) rate in the Z-axis, allow the machine to quickly maneuver around large complex workpieces for boosting productivity.

For increased accuracy, the machine's tilting/rotary table is supported at both ends and fitted to a highly rigid base without linear axis overhang and uses roller gear cams for the A- and C-axis drives. The A-axis provides a -120 degree to +30 degree range of movement, and the C axis rotates +/- 360 degrees for highly efficient 5-axis machining.

The X, Y and Z linear axes of the VARIAXIS i-600 integrate Mazak's MX Hybrid Roller Guide System to deliver levels of durability and reliability that result in long-term accuracy. The Mazak MX Hybrid Roller Guide System increases vibration dampening to extend tool life, handles higher load capacities, accelerates and decelerates quicker to shorten cycle times, consumes less oil for "Greener" operations, and lasts longer with less required maintenance.

To reduce workpiece interference and further increase machining efficiency through the use of shorter tools, Mazak outfitted the VARIAXIS i-600 with a compact spindle cartridge for a shorter machine spindle nose. A 30-tool (40, 80, 120 optional) automatic tool changer reduces chip-to-chip times down to only 3.4 seconds as it keeps the machine's water-cooled 18,000-rpm, 30 hp (22 kW) spindle supplied with tools. Plus, automatic tool changing is possible while the machine's A-axis is in any position. |

| Acerca de esta empresa: |

| Mazak Corporation is the North American manufacturing, sales and support arm of the leading international machine tool builder, Yamazaki Mazak Corporation (Oguchi, Japan). We produce machine tools and systems for the precision machining of metal parts, including CNC turning centers, horizontal and vertical machining centers, multi-tasking machining centers, turnkey cells, and software solutions to help customers achieve lean, efficient manufacturing operations. |

| Empresa: |

| Nombre de la empresa: |

Mazak Corporation |

| dirección: |

8025 Production Drive P.O. Box 970 |

| ciudad: |

Florence |

| provincia: |

KY |

| ZIP: |

41042 |

| país: |

U.S.A. |

| número de teléfono: |

+1-859-3421700 |

| FAX: |

+1-859-3421865 |

|

|

|